Автомобильные жгуты: как высокое напряжение, легкость и интеллектуальные технологии меняют отраслевой ландшафт?

2025-05-23

Автомобильные жгуты: как высокое напряжение, легкость и интеллектуальные технологии меняют отраслевой ландшафт?

Автомобильная отрасль Китая, движимая целями “двойного углерода” и технологиями интеллектуальных сетей, ускоряет переход к электрификации и интеллектуализации. В качестве основного носителя электрических систем автомобилей, индустрия жгутов сталкивается с двойными вызовами: технологическими инновациями и обновлением отрасли.

Высоковольтные жгуты: взрывной рост рынка новых энергетических автомобилей стимулирует технологическую эволюцию.

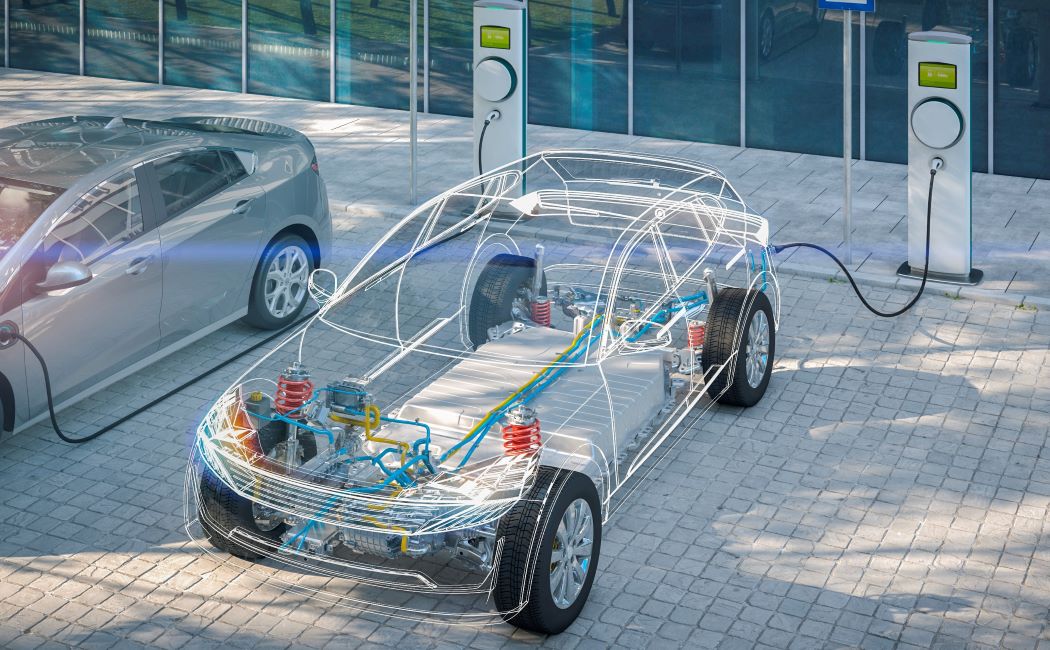

С увеличением проникновения новых энергетических автомобилей свыше 40% и ускорением распространения платформы на 800 В, резко возрос спрос на высоковольтные жгуты с высокой температурной стойкостью и отличными экранирующими свойствами. Медь илегированные провода и силиконовые изоляционные материалы станут основными; при этом жгуты должны соответствовать стандартам функциональной безопасности ISO 26262 и повышать устойчивость к электромагнитным помехам (EMI). Прогнозируется, что к 2025 году объем мирового рынка высоковольтных жгутов достигнет 18 миллиардов долларов (Китай займет 45%), а китайские компании разрабатывают сверхвысоковольтные жидкостные охладители для адаптации к платформам на 1000 В.

How can high voltage, lightweight, and intelligence reshape the industrial landscape of automotive wiring harnesses?

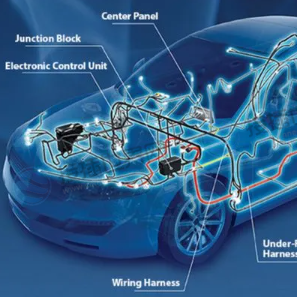

Driven by the “dual carbon” goal and intelligent networking technology, the Chinese automotive industry is accelerating its transformation towards electrification and intelligence. As the core carrier of automotive electrical systems, the wiring harness industry faces dual challenges of technological innovation and industrial upgrading.

High voltage wiring harness: The explosion of new energy vehicles drives technological iteration

With the penetration rate of new energy vehicles exceeding 40% and the accelerated popularization of 800V high-voltage platforms, the demand for high temperature resistant and high shielding performance high-voltage wire harnesses has surged. Copper alloy wires and silicone insulation materials will become mainstream, and wiring harnesses are required to meet the ISO 26262 functional safety standard to enhance their resistance to electromagnetic interference (EMI). The global high-voltage wire harness market is expected to reach $18 billion by 2025 (with China accounting for 45%), and Chinese companies are developing ultra-high voltage liquid cooled wire harnesses that are compatible with 1000V platforms.

Lightweight Materials: The Rise of Aluminum Wire Bundle and Carbon Fiber Composite Solutions

To cope with range anxiety and energy efficiency requirements, the lightweight solution of replacing traditional copper wire with aluminum wire will be applied on a large scale. Carbon fiber composite material sheath and thin-walled insulation technology further reduce the weight of the wiring harness, helping to reduce the weight of the entire vehicle by 10% -15%.

High speed data transmission: widespread use of Ethernet wiring harnesses in vehicles

L3+intelligent driving has driven a surge in demand for in car network bandwidth, with Gigabit Ethernet (GBASE-T1) wiring harness becoming standard. The twisted pair shielding structure and low latency signal transmission technology will dominate the data exchange architecture of ADAS and intelligent cockpit. The transmission rate of a single pair of twisted pair cables is 1Gbps, with a delay of less than 100ns, meeting the real-time decision-making requirements of L4 autonomous driving. Chinese enterprise Ideal L9 adopts Ethernet backbone network, reducing harness length by 40%. The Chinese enterprise Great Wall Motors Coffee Intelligent 2.0 platform connects 4 laser radars and 12 cameras through Ethernet harnesses, reducing data transmission latency by 60%.

Intelligent manufacturing: Industry 4.0 drives flexible production

AI quality inspection, machine vision, and digital twin technology have fully penetrated the wire harness factory, with a penetration rate of over 60% for fully automated crimping and laser marking processes. The MES system achieves full process digital management from design to delivery, significantly reducing costs and increasing efficiency. By 2025, the automation rate of domestic wire harness factories in China will reach 75%, labor costs will be reduced by 40%, and defect rates will decrease from 0.5% to below 0.1%.

Modular design: platform architecture reshapes supply chain

The platform based strategy of car companies promotes modular and integrated design of wiring harnesses, such as the BYD e-platform 3.0 of Chinese enterprise, which reduces the types of connectors from 120 to 30 and improves assembly efficiency by 25%. The standardization of connectors and the integration of zone control units (ZCUs) shorten the development cycle and reduce assembly complexity by 30%. Anbofu has launched the “Intelligent Vehicle Architecture (SVA)”, shifting wire harness suppliers from single part delivery to “modular system integration”, shortening the development cycle by 6 months.

Green and Sustainable: Breakthrough in Environmentally Friendly Materials and Recycling Technologies

The EU Battery Regulation (2027) and China’s dual carbon policy are forcing the industry to transform, and bio based biodegradable insulation materials (such as polylactic acid PLA) and halogen-free flame retardant sheaths are accelerating the replacement of traditional PVC. BASF Ultramid ® Bio (polyamide) uses castor oil as raw material, reducing carbon footprint by 60%, and has been widely applied on the wire harness sheath of Chinese enterprise SAIC Zhiji L7. The closed-loop recycling technology achieves a utilization rate of over 95% for copper and aluminum resources.

Wireless exploration: pilot of local wireless beam scheme

For short-range communication between sensors and actuators, wireless harness has been piloted in subsystems such as car doors and seats, reducing cable length by 20% -30%. For example, the BMW iX uses Bluetooth+UWB technology to transmit door unlock signals, reducing 12 harnesses and reducing weight by 0.8kg. However, in the short term, the “wired+wireless” hybrid architecture will still be the main approach. The reliability (99.999%) and real-time performance (<10ms) of wireless transmission still lag behind wired transmission, and the proportion of hybrid architecture will exceed 80% by 2025.

Thermal management technology: wire harnesses resistant to extreme environments become essential

The demand for 800V high-voltage fast charging and cold zone battery heating has given rise to a wide temperature range wire harness that can withstand -40 ℃~150 ℃. It adopts technologies such as polytetrafluoroethylene (PTFE) coating and liquid cooled heat dissipation pipes to ensure signal stability in high and low temperature environments.

Security and Testing: Upgrade of Simulation Verification Technology

Driven by the dual standards of functional safety (ISO 26262) and network safety (ISO/SAE 21434), the virtual simulation testing platform covers the verification of wire harness durability and electromagnetic compatibility (EMC), shortening the testing cycle by 50% and reducing the failure rate to below 0.1 ‰.

In 2025, the Chinese automotive wiring harness industry will undergo a four fold transformation of “high voltage, lightweight, intelligent, and green”. We need to focus on material innovation, process upgrading, and ecological synergy in order to seize the high ground in the global automotive supply chain transformation. Competition will not only be a technical competition, but also a contest of supply chain collaboration and ecological integration capabilities. Enterprises need to continuously cultivate in the three dimensions of materials, processes, and intelligence in order to lead industry transformation.